Feature your business, services, products, events & news. Submit Website.

Breaking Top Featured Content:

Drought In Taiwan Just Turned The Semi Shortage “Crisis” To “Critical”

Taiwan is suffering the “island’s worst drought in decades”, according to Nikkei. And this is terrible news for semiconductor manufacturers, who are being forced to make cuts on water usage while at the same time desperately trying to scramble and play catch-up with a drought of their own.

Taiwan is now planning to “further tighten water use in several cities that are home to a cluster of important manufacturers,” including plants in Taoyuan, Taichung, Hsinchu and Miaoli. They are going to be asked to cut consumption by up to 11%. Chiayi and Tainan, where Taiwan Semiconductor is based, will be asked to take a 7% cut.

All of these cuts come on top of another 7% cut already put into effect last month.

One chipmaker executive told Nikkei: “All the industries are concerned whether the situation will be alleviated soon. … No one wants to see the worst-case scenario of anyone being forced to dial back production capacity due to water issues.”

Companies like TSMC use 156,000 tons of water a day. Water quality is “is extremely critical to chip production lines and the processes. … It could affect product performance, so that needs to be handled very carefully,” one insider told Nikkei.

“So far the situation is manageable, but if it does not rain properly and continues like this till the end of May, that would be a real big problem,” they concluded.

Meanwhile, TSMC is now considering trucking water in to supplement its reservoirs. “Deployments are still limited and the main purpose is to get the involved staff prepared for possible future needs,” a TSMC spokeswoman said.

United Microelectronics is considering doing the same. CFO and spokesperson Liu Chi-tung told Nikkei: “As the water-saving rate needs to increase to 11%, we need the support of additional water trucks. Currently we only need a small percentage of additional water, but the company will adjust accordingly based on the dynamics.”

Unimicron CFO Michael Shen said on an earnings call Wednesday: “We’ve been reserving water and we will use rental water trucks to support our use if necessary. If we keep having no rain … it will be difficult for us to address the issue.”

No typhoons hit the island in 2020, despite Taiwan averaging three major storms a year that bring much needed rain.

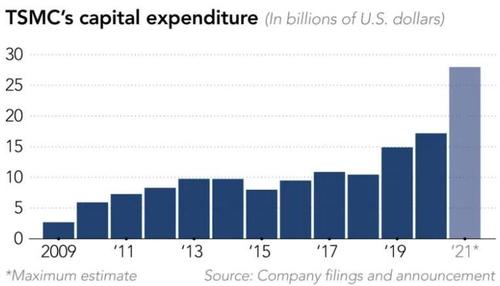

We just documented weeks ago how critical Taiwan would be in getting the semiconductor industry back up and running. We noted that Taiwan Semiconductor Manufacturing is rushing to try and build new facilities through the Chinese New Year in order to meet demand.

TSMC is one of the biggest suppliers of chips to company like Apple, Google and Qualcomm. As a result of a worldwide shortage in chips that was brought on due to the pandemic, they are now rushing to try and get a new factory in the southern Taiwanese city of Tainan built. Construction the new facility will take place throughout 2021, with completion expected in 2022.

Earlier this month we noted that the semi situation had been turning dire and was now being referred to as the “most serious shortage in years”. Qualcomm’s CEO said weeks ago that there were now shortages “across the board”.

And it wasn’t just Qualcomm executives speaking out: other industry leaders warned in recent weeks that they are susceptible to the shortages. Apple said recently that its new high end iPhones were on hold due to a shortage of components. NXP Semiconductors has also warned that the problems are no longer just confined to the auto industry. Sony also said last week it may not be able to to fully meet demand for its new gaming console in 2021 due to the shortage. Companies like Lenovo have also been feeling the crunch.

Neil Mawston, an analyst with Strategy Analytics, said: “The virus pandemic, social distancing in factories, and soaring competition from tablets, laptops and electric cars are causing some of the toughest conditions for smartphone component supply in many years.”

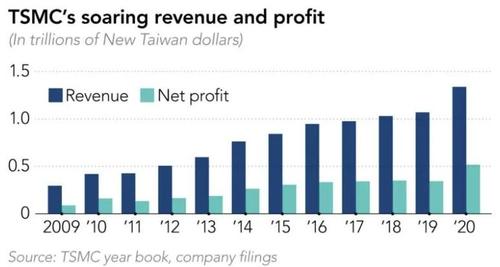

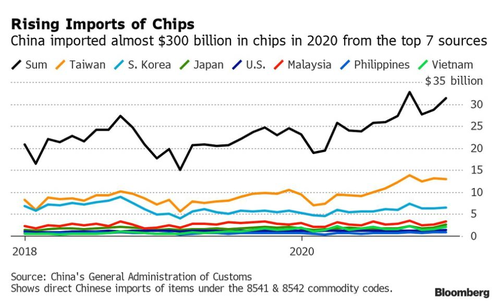

At the center of the shortage is Taiwan Semiconductor Manufacturing Co., who now sits astride a larger political crisis between China and Taiwan while Biden officials in the U.S. work to find solutions, not only for the semiconductor issues, but for the larger conflict developing between the two nations.

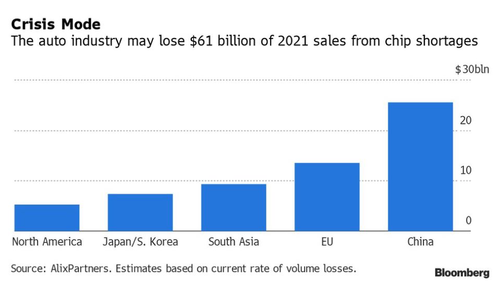

While the extent of the damage on consumer electronics remains to be seen, the shortages are expected to cost $61 billion worth of sales in the auto industry. Recall, we noted weeks ago that GM and Ford had joined Nissan in cutting production due to the shortage.

Several weeks ago the U.S. automaker announced that the shortage would “impact production in 2021”, according to StreetInsider. The company said in a statement that “semiconductor supply for the global auto industry remains very fluid”.

It continued: “Our supply chain organization is working closely with our supply base to find solutions for our suppliers’ semiconductor requirements and to mitigate impacts on GM. Despite our mitigation efforts, the semiconductor shortage will impact GM production in 2021.”

Tyler Durden

Thu, 02/25/2021 – 18:40

Continue reading at ZeroHedge.com, Click Here.